Product

Solutions

Resources

Company

About Cube

Explore our vision and team

Careers

Help shape the future of FP&A

In the News

Cube featured in top publications

Security

Enterprise-grade, cloud security

Newsletter

.png)

A newsletter for finance pros—by finance pros. Get practical, strategic finance insights from those who’ve been there—straight to your inbox.

Manufacturing

fp&a for manufacturing

Take control of your financial future

Seamlessly manage workforce needs and supply chain operations, control costs, and provide accurate forecasts for units, prices, and margins by SKU to optimize revenue with Cube.

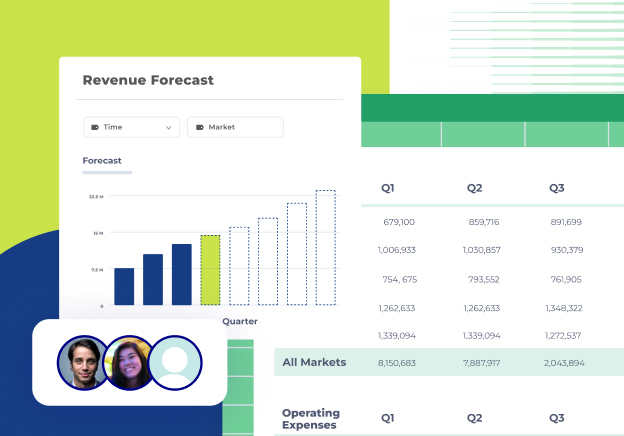

How Cube Works

-

Loved by finance pros at

-

-

.png)

-

-

-

Why leading manufacturers choose Cube

Improve efficiency

Consolidate data from your inventory tools, spreadsheets, and ERP to plan for supply chain risks, resource needs, or machinery downtime.

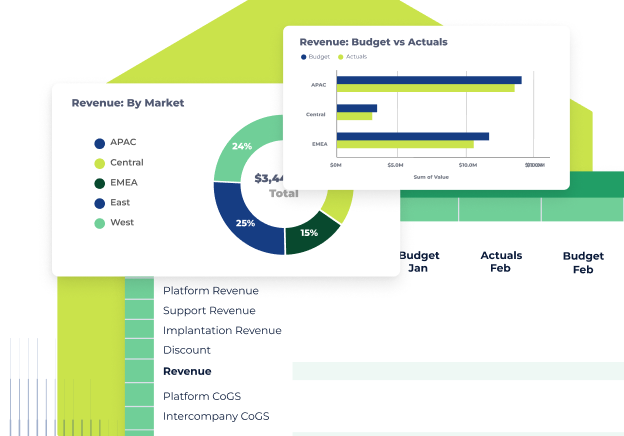

Plan smarter

Leverage driver-based planning that links production metrics to financial models, enabling accurate resource allocation and real-time tracking.

Think strategically

Optimize staffing levels, control labor costs, balance budgets, and ensure operational continuity without compromise.

Manage FP&A Your Way

Annual Budgets

Gross Margin ROI (GMROI)

Driver Based Planning

Income Statements

Cash Flow Reporting

Market Trend Analysis

Strategic Initiative Evaluation

Cost-Benefit Analysis

Monthly/Quarterly Forecasting

Finance teams trust Cube to transform their FP&A

Cube will help organize your existing chaos and scale as you continue to grow.

Dustin Walsted

VP of Finance, Technology, HR

Cube has eliminated the human error aspect, which has helped our data become way more accurate.

Alex Leavitt

Director of FP&A

Powering 1,000s of finance professionals in every industry.

See cube in action

With Cube, finance teams can focus on what matters—guiding the business forward with speed, precision, and confidence.

What is Cube and how does it support manufacturing financial planning in Excel and Google Sheets?

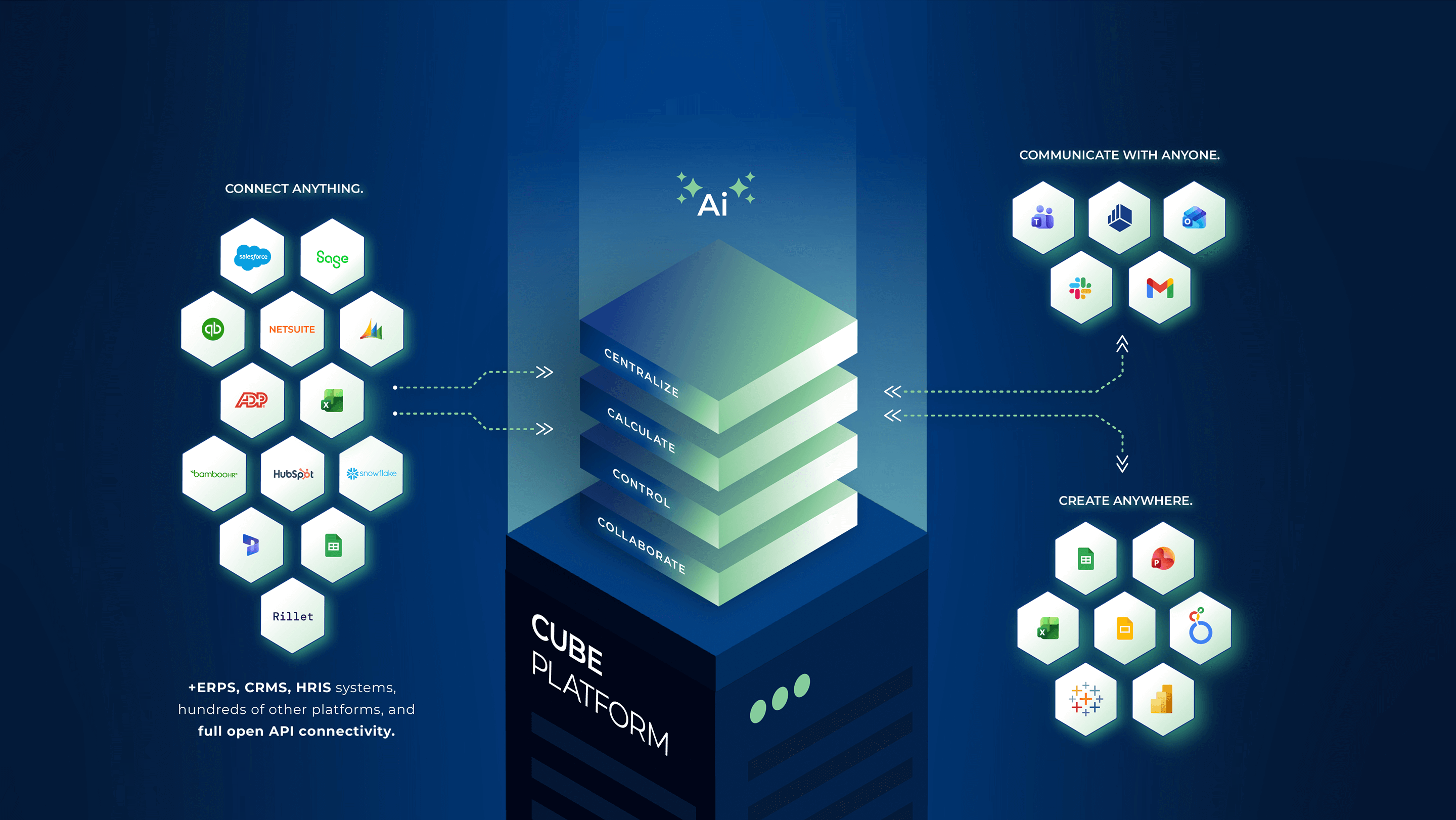

Cube is a no-code FP&A platform that integrates seamlessly into Excel and Google Sheets, as well as Slack and Teams, on both Macs and PCs. Manufacturing finance teams can continue using their preferred tools while gaining centralized control over data, one-click syncs, and automated reporting and workflows.

How does Cube help with plant-level performance tracking and forecasting?

Cube consolidates data from your ERP, MES, and other operational systems into a centralized, multi-dimensional model. This enables plant-level tracking of costs, capacity utilization, and production KPIs. Teams can forecast output, margins, and labor needs across facilities in real time, directly in their spreadsheets.

Can Cube support scenario planning for material costs or production delays?

How does Cube enable driver-based planning for manufacturing teams?

What data integrations does Cube offer for manufacturing FP&A teams?

Cube integrates with ERPs (like NetSuite, SAP, Oracle), MES systems, inventory tools, and more. It supports no-code data ingestion, mapping, and cleaning across entities, facilities, or currencies, eliminating the need for manual imports and VLOOKUPs.

How secure is Cube for large manufacturing enterprises?

What manufacturing KPIs and variance analysis can Cube support?

How does Cube support collaboration between finance, operations, and supply chain teams?

Does Cube support workforce and labor planning for manufacturing?

Absolutely. Cube includes templates and data connections for workforce planning across plants, shifts, or roles. Model overtime, labor cost per unit, hiring plans, and union/non-union workforce mixes, directly in Excel or Google Sheets, synced to Cube’s centralized data model.

Still have questions?

.png)