What is sales and operations planning (S&OP)?

Sales and operations planning (S&OP) is a meticulous business management strategy that balances supply and demand. In other words, it tries to ensure that the supply of one or more products matches customer demand as closely as possible.

It does this first by forecasting demand for a specific period, then by determining what operations need to do in order to meet that demand. S&OP is a critical process that coordinates strategy across multiple departments. These include sales, marketing, manufacturing, and supply chain planning.

Consider that S&OP can be broken down into sales and operations. The goal is to match operational plans to sales forecasts. This ensures that the right products are always available at the right times, in the right amounts, and at the right costs. The goal is that businesses will never miss out on revenue opportunities by failing to meet demand.

S&OP is a holistic planning process that fine-tunes business operations across the company. When focused on a common goal, each department uses its capacity to meet the specific supply production objectives.

S&OP is usually done once per month, but since there's a lot to it, the entire planning cycle can take four weeks. It provides a medium-to-long-term roadmap, extending 18-36 months into the future. S&OP is a rolling forecast, and it's continuously updated to meet changing market conditions.

Why use an S&OP planning process?

S&OP comes with many benefits. Some of the most important are:

1. Improve customer service

The main goal of a company is to deliver products to customers in a timely fashion that meets demand levels.

When production plans and supply chains are optimized to do that, you get happy customers.

This is also true when products are priced right for the current market. That's something that comes from the in-depth understanding of supply and demand that's the focus of sales and operations planning.

2. Improved inventory management

Excess inventory can be a huge financial drain on a company, especially if storage costs are high.

By matching supply to demand, S&OP helps ensure you pay as close to the exact amount you need to pay for inventory. There's no need to hold onto inventory for longer than necessary.

You also avoid the loss of revenue that comes with stock-outs. Optimizing inventory turnover is a balancing act—investing in a data-driven S&OP process is the best way to balance it.

3. Optimized production costs

Production is only as good as its ROI—creating products that don't sell well wastes employee time and talent.

By running solid sales forecasts and matching production plans to them, you ensure you're only producing what will sell.

By extension, you keep your cost of goods sold as optimized as possible.

4. Better ability to respond to crises

Scenario planning is a significant component of S&OP. It's impossible to predict everything, especially—as the last few years have taught us—in regard to supply chains. When companies prepare for changes in supply and demand, they're much more able to quickly pivot.

If one of your suppliers can't get materials to you fast enough to meet production demand, will you still be able to meet consumer demand for that period? Probably not. Having a scenario plan—like an alternative supplier—helps you react quickly. It means not missing out on revenue opportunities or customers to competitors whose supply lines may not have been affected.

Employ scenario planning as part of S&OP to be proactive instead of reactive.

5. Increased cooperation

Communication between departments is critical, even if it's not done to accomplish a specific goal in S&OP.

One of the best parts of S&OP is that it normalizes a culture of communication. At the same time, it channels the business towards higher productivity and cost savings.

When departments aren't working together to achieve a common goal, things tend to be unfocused. Production may understand that it needs to make a ballpark amount of product to fulfill demand.

The company will acquire revenue, but it'll be losing money in other ways. Perhaps there's too much inventory, as sales did not create granular forecasts and communicate them to production. Or customer service is struggling, as infrastructure can't deliver all these products on time.

So S&OP ensures that broad goals are completed with the least possible waste across departments. Operations planning benefits S&OP goals and individual departments by streamlining operating costs.

When all departments view only one source of data and consensus plan, everything works like a well-oiled machine. Exactly how a company should.

All the above benefits boost the company's profitability and standing in the industry.

How to make your sales and operations plan

So, you're convinced that S&OP is worthwhile. How do you do it?

S&OP is a data-based process. It makes sense that the first step involves gathering data.

This data will inform each of the subsequent steps.

1. Data gathering

Relevant data for S&OP include sales forecasts, historical sales data, success rates of past marketing plans, and production and inventory requirements. Teams should source this information from across departments.

This step is the foundation of the whole process. Quality data ensures quality results, but flawed data ensures flawed results.

2. Demand planning

In demand planning, you'd look at consumer trends and historical data to forecast customer demand for specific products. This step produces the number you aim for—the quantifiable amount customers want.

This number is given in either units or terms of revenue. Demand planning also informs your customer service policies.

Be sure to include all factors that can affect demand, such as seasonality.

3. Supply planning

This is where you'd figure out how the company can match supply to projected demand.

That involves answering a variety of questions. Is your supply chain capacity enough to gather the necessary materials to fulfill demand? Do you have the right amount of machinery to meet the demand in the appropriate timeframe?

If demand is exceptionally high, will infrastructure be able to deliver all products to customers within the demand timeframe?

Supply planning also evaluates how many employees will be required to meet this goal and what skills they need. It´s here that S&OP and workforce planning intersect.

If you lack capacity, you'll need to make adjustments. Here you can see how S&OP can guide the direction of the entire business. For instance, by enlisting different suppliers or hiring more employees.

4. Operations planning

Operational planning must be carried out in each department to ensure the overall S&OP goal is met.

Determining an operational process involves breaking down the S&OP plan—meeting specific demand—into steps for each. For instance, sales must ensure they have the right team members to meet projected sales numbers within the timeframe. Production needs to determine their daily quota, and so on.

5. Pre-S&OP meeting

The Pre-S&OP meeting is when the different departments gather to discuss their data results. Here, the plan would be fine-tuned to ensure the two previous steps—demand and supply—are correctly aligned. If there are any gaps, run a root cause analysis to find the right solutions

Discrepancies across departments get adjusted to meet goals.

The Pre-S&OP meeting would also make recommendations for the agenda of the next phase—the executive meeting.

6. Executive meeting

This is where the plan is finalized. It's called executive planning because it involves the CEO of the company. At this stage, the CEO needs to make sure the plan gels with the overall direction of the company.

In other words, the operational plans established by the S&OP process won't upset the overall corporate strategy. They're meant to work together. The CEO will make the final call on the shape of the S&OP plan.

The plan would be refined in this phase by looking at different scenarios.

After all, it's always possible that supply and demand could change, and one critical component of a solid S&OP plan is agility. By preparing, you ensure sudden market changes—such as supply chain disruptions—have the least impact possible.

7. Execution

Once the plan has been approved by the executives, it's ready to be implemented.

Before execution, it's crucial to communicate the plan to all internal and external stakeholders (like suppliers). For an S&OP plan to work, clear and documented ownership needs to be taken for each individual component of it.

That way, when problems are identified, it will be clear where changes need to be made.

8. Performance review

So the plan has been executed—how did it work out? Do any adjustments need to be made for next month? Here, you'd measure KPIs like sales and inventory levels. Did you have the exact right amount of inventory (or as close as possible)?

Do variance analysis by comparing actuals to forecast. As solid as forecasts can be, the market isn't stagnant, and finding these variances is integral to the process.

Optimize for supply and demand changes. You'd make adjustments that would carry over to the next month and then repeat the whole process from step one to step eight.

Other considerations for successful S&OP

S&OP can reveal if you need to improve operations—for example, whether you'll need new suppliers. Your current suppliers may not be able to meet demand without bottlenecks.

It can also reveal if products lack demand and should be sunsetted.

S&OP evaluates proposals for new suppliers and products by seeing if these would fit into a hypothetical S&OP plan. It also looks at proposals for expanding into new markets by gauging demand and the company's ability to meet that demand.

S&OP roles defined

Standard S&OP practice involves designating specific people for specific parts of the process. Let's take a quick look sales the roles in sales and operations teams:

The executive sponsor

The executive sponsor is the person who chairs the executive meeting and communicates the plan to all stakeholders.

They ensure each department adheres to the plan's final version in the executive meeting.

This person is typically the CEO.

Sales and marketing representatives

Sales and Marketing representatives oversee the sales forecast process.

There can be one or more, depending on the company's size. These representatives ensure sales forecasts are run regularly—at least once a month—based on solid data (market trends, historical data, etc.).

They also do variance analysis on past sales forecasts and try to implement those findings into the new plans.

Production and inventory management representatives

These team members provide insights into production capacity and lead times.

They let other branches know what can be realistically accomplished.

Demand planner

The demand planner is responsible for forecasting market demand.

They work with sales to ensure the demand plan they develop reflects accurate sales forecasts.

Supply planner

Responsible for developing the supply plans. They must work closely with production and inventory management representatives to align the supply and production plans.

Most importantly, they must ensure sufficient capacity to meet the supply plan.

How software fortifies S&OP plans

S&OP is an invaluable but complicated process requiring the successful alignment of many moving parts.

However, it can determine the best way to use business assets efficiently to meet customer demand when you do it right. In the end, this smooths out the overall function of your business.

As in most business processes, software can help.

Automation is especially useful in sales & operations planning software. When teams use automation, data gathering won't take up so much time. There's also zero chance of transcription error—even one error can upset the effectiveness of your S&OP plan. You've spent about a month working on it, so if manual transcription can be avoided, why not ensure that's the case?

An S&OP plan should be as detailed as possible without taking up so much time that departments can't fulfill their primary obligations. This is precisely what's enabled through automation.

Forecasting—an integral component of S&OP plans—can also be automated. Here, again, you avoid the risk of human error, implying what'll ultimately be a flawed operating plan.

What to look for in S&OP software

S&OP plans are only as good as they are agile. Some software like Cube includes specific scenario planning capacities—a necessary part of any S&OP software.

You´ll also want software that keeps track of user-defined KPIs so that you can evaluate the effectiveness of your S&OP plan once it's been executed.

To fully understand your situation, you need software that integrates with ERPs like Sage and accounting programs like Oracle. Sometimes, a program is best at one thing—it may be op software, for example, that streamlines the operations planning process and execution.

The first foundational step of S&OP is data gathering. Therefore, you'll want software that gathers data automatically.

S&OP software examples

Some examples of S&OP software include:

1. Cube

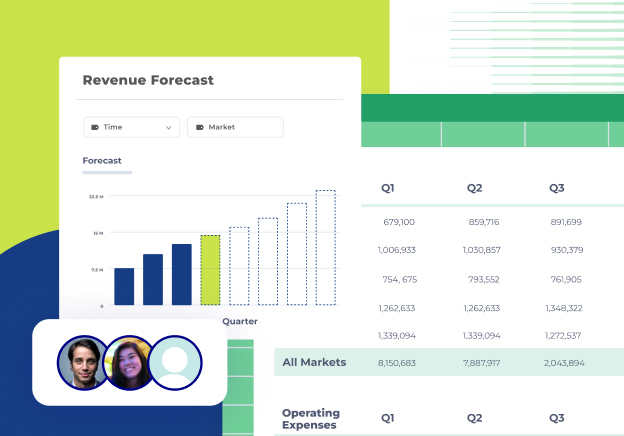

Cube is a powerful and intuitive FP&A tool and our #1 choice for FP&A software. Here's a quick overview of Cube:

- The first spreadsheet-native FP&A software that empowers teams to drive better planning and performance without changing how they work.

- Eliminates manual work and provides the real-time insights finance needs to strategize with speed and agility.

- Pairs the flexibility and familiarity of your spreadsheets with the control and power of enterprise software.

- Implements quickly. Cube gets you up and running in days, not months, which means faster time to value at a lower cost.

- Connects with any source system, browser, and sheet in moments, so you don't have to change your work.

- Access to an award-winning customer team with deep FP&A experience.

Best For:

Cube’s simple and intuitive experience makes it an excellent choice for mid-market companies that want to start fast with scalable, enterprise-grade technology at a reasonable price.

Essential functionality from Cube includes:

- Automated data consolidation

- Sharable planning templates

- Customizable dashboards and reports

- Scenario planning and analysis

- Bidirectional Excel and Google Sheets integration

- Approval workflow

- Drill-throughs and audit trails

- User-based controls

- Centralized formulas and KPI

These FP&A software features translate to easier reporting and KPIs, more accurate forecasting and budgeting, faster close and consolidation cycles, and collaborative teamwork for more control and fewer mistakes.

Integrations:

Cube is built to work directly with most finance and business systems including ERP, CRM, HRIS, Business Intelligence systems, and more. Cube has bi-directional integration with Google Sheets and Microsoft Excel, which gives customers an incredible amount of versatility to choose the user experience that is right for them and their business teams.

Pricing:

Cube offers multiple pricing tiers based on company and size, FP&A needs, and advanced integrations.

Most teams onboard in 2 weeks—no consultants required.

Pricing tiers include:

- Essential capabilities for small finance teams looking to improve speed, accuracy, and scalability.

- Premium capabilities for growth-stage companies looking to scale reporting, planning, and performance.

- Advanced capabilities for large, pre-IPO, and public companies needing enterprise-grade features for best-in-class performance.

2. Anaplan

Anaplan lets you mobilize complex scenario planning to the smallest detail, intelligently forecast the biggest picture, and empower teams to make decisions faster. Their enterprise-wide solutions connect your strategy to your outcomes and layers of accountability connected to a single source of truth

For Finance, Anaplan specifically provides FP&A solutions to connect your people, data and plans across your organization to empower the right decisions quickly. Capabilities include planning, budgeting, and forecasting; specialty finance planning; operational planning, which delivers better and faster decision-making; automated cost management practices; and connected financial and operational plans.

Best For:

Anaplan is good for large enterprise customers with a strong IT team ready to lead an enterprise-scale transformation initiative.

Pricing:

Anaplan offers basic, professional, and enterprise packages with a complex array of included features, integrations, and capabilities. Prices are not listed on their website.

- Adaptive Planning by Workday

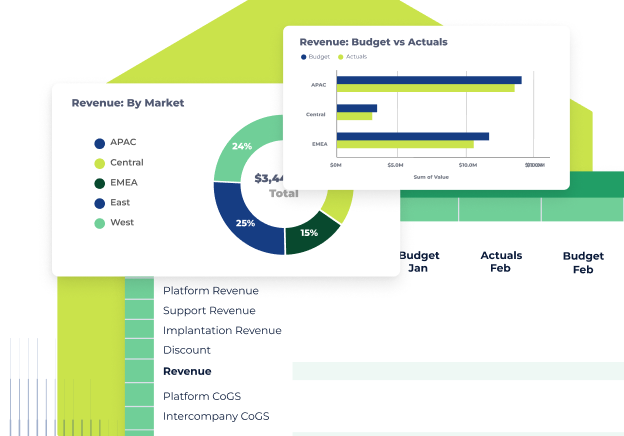

3. Workday Adaptive Planning

Workday Adaptive Planning, formerly Adaptive Insights, provides enterprise planning software to upgrade planning, modeling, budgeting, and forecasting. Their solutions cover financial, workforce, and sales planning to promote collaboration across the enterprise without manual spreadsheets or clunky legacy systems. Workday Adaptive Planning is a financial management solution.

Workday Adaptive Planning for finance provides explicitly flexible, scalable financial planning and analytics for large enterprises; powerful modeling for any size business; reporting that’s easy to use and always up to date, and real-time financial consolidation that accelerates your financial close. The solution also covers FP&A solution needs for modeling, collaboration, analytics, management reporting, board reporting, scenario planning, and financial consolidation.

Best For:

Their strong capabilities outside of Finance and FP&A make Adaptive Planning a good choice for large enterprises seeking a transformational, company-wide FP&A solution.

Integrations:

The Workday Adaptive Planning integration framework works seamlessly with cloud-based, on-premise, and file-based applications.

Pricing:

Workday Adaptive Planning offers pricing packages considering package and features, company size, and seat types. Prices are not listed on their website.

4. Vena

Vena offers a complete planning platform to unite people, processes, and systems. They offer pre-built solutions to automate time-consuming tasks so you can spend less time checking your data's accuracy.

Specific capabilities include financial planning and analysis, integrated business planning, financial reporting, regulatory compliance reporting, and financial close management. Vena focuses on helping companies support overall growth and refers to its platform as a “growth engine.”

For Finance, Vena offers “pre-configured” FP&A software that provides a prescriptive approach to corporate performance management but can be customized to meet specific business needs and industry requirements.

Best For:

Vena is ideal for companies that need the fixed process and planning guidance of pre-built FP&A solutions or that have the resources to uniquely customize those pre-built solutions for their own needs.

Pricing:

Pricing tiers and details are not listed on their website.

Conclusion

S&OP is a sometimes overlooked process that can make a huge difference in your business. The data bears this out. Companies that prioritize S&OP showed:

- 15 % less inventory

- 1/10th of stock-outs

- 17 % improved perfect order fulfillment

These days, there's little excuse not to use some planning software.

If you're exploring options, you should consider Cube.

Cube gives you the power of enterprise-level software with the flexibility and familiarity of spreadsheets. It natively integrates with Excel and Google Sheets to streamline sales and operations planning.

Sound interesting? Request a free demo by clicking on the image below:

.png)

.png)

![Workday Adaptive Planning: Complete review & top alternatives [2026]](https://www.cubesoftware.com/hubfs/Cube%20website%20-%202026/Blog%20Post%20-%20Featured%20Images/Featured%20-%20Pie%20Dashboard.png)